What kind of heat sealers do we use?

The Thermalizing machine (sublimation machine – heat press) is in charge of properly adhering a Thermo-adhesive reinforcement (interlining) to the fabric, the machine consists of three specifications that we must consider obtaining an optimal result:

- Temperature : Controlled by °C

- Pressure : Controlled by N/cm² or by bars. (1 bar cm²)

- Time : Controlled by seconds.

- 8-in-1 heat fixer: This machine is useful in various fields in the area of sublimation, it has 8 interchangeable accessories, this machine can be used on cylindrical objects (mugs, thermoses…) flat materials or factory, caps, plates.

- 5 in 1 Thermofixer : This machine has 5 independent resistances to sublimate cylindrical objects (mug, thermos…) .

- Heat fixer for pencils or pens: this machine can sublimate 5 cylindrical objects at a time, such as pencils, pens, straws or plastic straws… among others.

- Cap Heat Fixer: This semi-automatic machine has a timer that automatically raises the heat resistance when the fixation is ready.

- Flat Semiautomatic Heat Press: This heat press has a 40×60 cm work area, used on flat materials or factory, it has a timer that automatically raises the heat resistance when the fixation is ready.

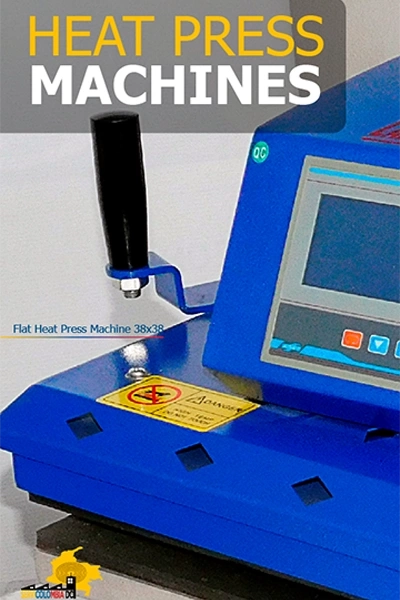

- Flat Heat Press: This heat press has a 38×38 cm work area, used on flat materials or factory.

|

|

|